The Intricate World of Diecasting: Precision in Manufacturing

The Intricate World of Diecasting: Precision in Manufacturing

Blog Article

Diecasting is one of the most important processes in modern manufacturing, playing the most important role in making intricate metal components with accuracy and efficacy. The process involves pushing the molten metal with high pressure into mold cavities, producing parts with exceptional dimensional accuracy and high finish on the surface. As industries evolve and demands for quality components rises, diecasting has continued to demonstrate its worth especially in industries that require massive production of highly intricate components. This article explores the diecasting process, its advantages, material selections, and the wide range of applications across various sectors.

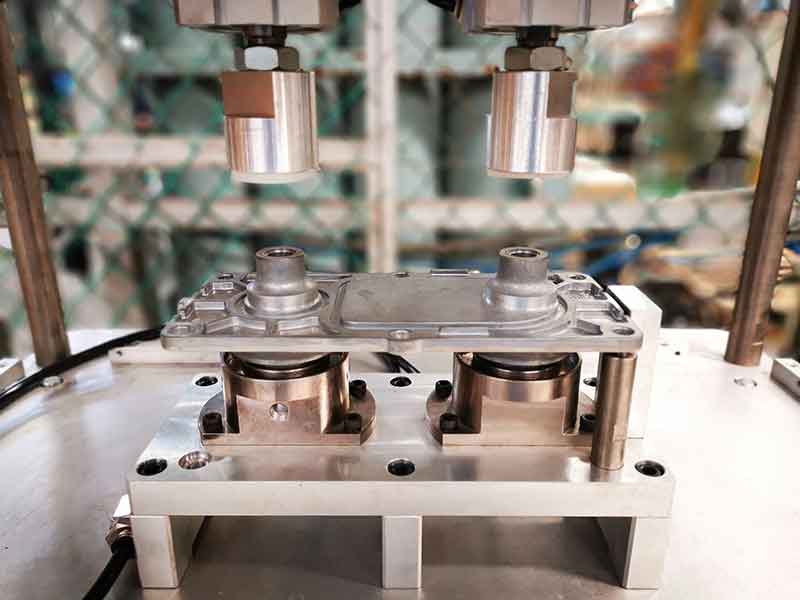

Diecasting begins with the design of the mold, or the die. It is constructed of steel hardened that can withstand extreme pressure and temperatures. When the mold is ready metal alloys, such as magnesium, aluminum, zinc or copper, are heated until they are melted. The molten material is introduced into the mold at extreme pressure. This ensures that it covers all the parts of the mold, which includes detailed sections as well as thin walls. This pressure will be maintained until the molten metal is solid, and at that point, the mold is unveiled, and the part that has been formed is released. This high-pressure method ensures that the final product is precise that it requires little extra machining or final.

One of the biggest benefits of diecasting is its effectiveness in mass production. When the dies are made and shaped, they are able to produce thousands of identical components with the least amount of variation. This high level of repeatability is vital for companies which require huge quantities of consistent components. Furthermore, diecasting is recognized as a material that is efficient. This process produces very little debris, as any metal that is not used is re-usable in subsequent casting cycles. It not only lowers cost of materials but also helps to promote sustainable manufacturing by reducing resource consumption and waste. The combination of high productivity, speed of production, and material efficiency makes diecasting an attractive option in the quest to maximize their production processes.

Diecasting can also provide significant benefits in terms of the mechanical properties and performance. Diecast components are well-known for their strength and durability as they are the most important characteristics for components used for demanding tasks. The structure of the fine grain that is formed during the rapid cooling of the metal contributes to the desirable characteristics, which makes diecast parts suitable for use in highly stressed environments. Diecasting also allows the incorporation of thin walls and complicated elements without degrading the quality of the product. This feature is particularly beneficial when it comes to aerospace and automotive industries, where reducing weight but maintaining strength in the structure is vital to increase the efficiency of fuel and overall performance. To receive extra information please check out https://www.senadiecasting.com.my/

Diecasting's versatility extends to its wide range of possibilities. In the automotive industry, diecast components are used in engines, transmissions, and structural parts, contributing to more efficient and lighter vehicles. In the field of electronics, diecasting can be employed for the production of housings, heatsinks, and connectors. This ensures optimal temperature management and long-lasting. Appliances for the home, power tools, and toys also benefit in diecasting's accuracy and efficacy in the production of components that range in size from knobs, handles, and handles and internal components. The process's adaptability to various metals as well as its capability to produce parts with intricate designs makes it ideal for a wide range of sectors, each benefiting from the unique advantages of diecasting.

Diecasting stands at the top of technology for manufacturing, providing accuracy, productivity, and versatility unlike other manufacturing processes. The ability to create sophisticated, high-quality parts with exceptional mechanical properties makes it indispensable in many sectors, from automotive to consumer electronic products. The efficacy and efficiency savings associated with diecasting demonstrate its worth in high-volume manufacturing, and its flexibility guarantees that it is able to accommodate the ever-changing demands of modern manufacturing. In the midst of industries pushing the boundaries of innovation and productivity, diecasting is expected to continue to be an essential tool providing the basis for advancements, and also facilitating manufacturing of the most cutting-edge items which shape the world.